AMC(L) Chemical Process Magnetic Drive Pump

Product Overview

The AMC-F series fluoroplastic-lined chemical process magnetic drive pumps are a new type of chemical environmental protection magnetic drive pumps with high corrosion resistance, high durability, and high safety. Designed in compliance with the HG/T2730 standard, this series of pumps is widely used in various medium-to-high-end chemical liquid circulation fields. The series adopts cast iron or ductile iron shells lined with F46, PFA, and other injection-molded materials through one-time molding. It is designed with a self-circulating heat dissipation and cooling structure as well as a heat insulation design, ensuring the pump's high efficiency and long service life.

Product Features

- High Corrosion Resistance Performance

- Heat-Free Magnetic Coupling Technology

- Load-Bearing System Standard-Equipped Pressureless Sintered Silicon Carbide

- High-Efficiency Hydraulic Energy-Saving Technology

Technical Specifications

| Model | Diameter | Motor | Performance Parameter | Efficiency (%) | NPSHr (m) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Inlet | Outlet | Power (kW) | Power (Hp) | Voltage (V) | Frequency (Hz) | Speed (r/min) | Rated Head (m) | Rated Capacity (m³/h) | |||

| AMC32-25-125A | DN32 | DN25 | 1.5 | 2 | 3ø-380 | 50 | 2760 | 20 | 3.2 | 42 | 2.5 |

| AMC50-32-160A | DN50 | DN32 | 2.2 | 3 | 3ø-380 | 50 | 2760 | 32 | 3.2 | 28 | 2.5 |

| AMC32-25-125 | DN32 | DN25 | 1.5 | 2 | 3ø-380 | 50 | 2760 | 20 | 6.3 | 45 | 2.5 |

| AMC50-32-160 | DN50 | DN32 | 2.2 | 3 | 3ø-380 | 50 | 2760 | 32 | 6.3 | 41 | 2.5 |

| AMC50-40-200A | DN50 | DN40 | 5.5 | 7.5 | 3ø-380 | 50 | 2900 | 50 | 6 | 26 | 2.8 |

| AMC50-32-125 | DN50 | DN32 | 3 | 4 | 3ø-380 | 50 | 2900 | 20 | 12.5 | 52 | 2.8 |

| AMC50-32-160L | DN50 | DN32 | 4 | 5 | 3ø-380 | 50 | 2900 | 32 | 12.5 | 46 | 3 |

| AMC50-40-200 | DN50 | DN40 | 7.5 | 10 | 3ø-380 | 50 | 2900 | 50 | 12.5 | 42 | 3 |

| AMC50-32-250A | DN50 | DN32 | 15 | 20 | 3ø-380 | 50 | 2900 | 75 | 12.5 | 32 | 2.2 |

| AMC50-32-250 | DN50 | DN32 | 22 | 30 | 3ø-380 | 50 | 2900 | 80 | 20 | 40 | 2.2 |

| AMC65-50-125 | DN65 | DN50 | 4 | 5 | 3ø-380 | 50 | 2900 | 20 | 25 | 62 | 3 |

| AMC50-40-160 | DN50 | DN40 | 7.5 | 10 | 3ø-380 | 50 | 2900 | 35 | 25 | 59 | 3 |

| AMC65-40-200 | DN65 | DN40 | 11 | 15 | 3ø-380 | 50 | 2900 | 50 | 25 | 52 | 3.5 |

| AMC65-40-250A | DN65 | DN40 | 22 | 30 | 3ø-380 | 50 | 2900 | 70 | 30 | 48 | 3.2 |

| AMC65-40-250 | DN65 | DN40 | 30 | 40 | 3ø-380 | 50 | 2900 | 80 | 38 | 50 | 3.5 |

| AMC80-65-125 | DN80 | DN65 | 7.5 | 10 | 3ø-380 | 50 | 2900 | 23 | 50 | 68 | 3.5 |

| AMC80-65-160A | DN80 | DN65 | 15 | 20 | 3ø-380 | 50 | 2900 | 35 | 50 | 65 | 3.2 |

| AMC80-65-200A | DN80 | DN65 | 18.5 | 25 | 3ø-380 | 50 | 2900 | 50 | 50 | 63 | 3.5 |

| AMC100-80-125 | DN100 | DN80 | 11 | 15 | 3ø-380 | 50 | 2900 | 20 | 100 | 73 | 3.5 |

| AMC80-65-160 | DN80 | DN65 | 18.5 | 25 | 3ø-380 | 50 | 2900 | 32 | 100 | 74 | 3.5 |

| AMC80-65-200 | DN80 | DN65 | 22 | 30 | 3ø-380 | 50 | 2900 | 50 | 100 | 73 | 4 |

| AMC125-80-160 | DN125 | DN80 | 30 | 40 | 3ø-380 | 50 | 2900 | 41 | 120 | 76 | 4 |

| AMC125-80-200 | DN125 | DN80 | 37 | 50 | 3ø-380 | 50 | 2900 | 50 | 150 | 79 | 4.5 |

| AMC125-100-200 | DN125 | DN100 | 55 | 75 | 3ø-380 | 50 | 2900 | 50 | 200 | 80 | 4.5 |

| AMC125-100-250 | DN125 | DN100 | 15 | 20 | 3ø-380 | 50 | 1450 | 20 | 170 | 72 | 2 |

| AMC150-150-200 | DN150 | DN150 | 55 | 75 | 3ø-380 | 50 | 2900 | 30 | 300 | 64 | 6 |

*The above characteristic testing is based on water transfer at normal speed under 20°C. The performance parameter error is approximately ±10%. Pump performance varies depending on the proportion and density of the liquid medium.

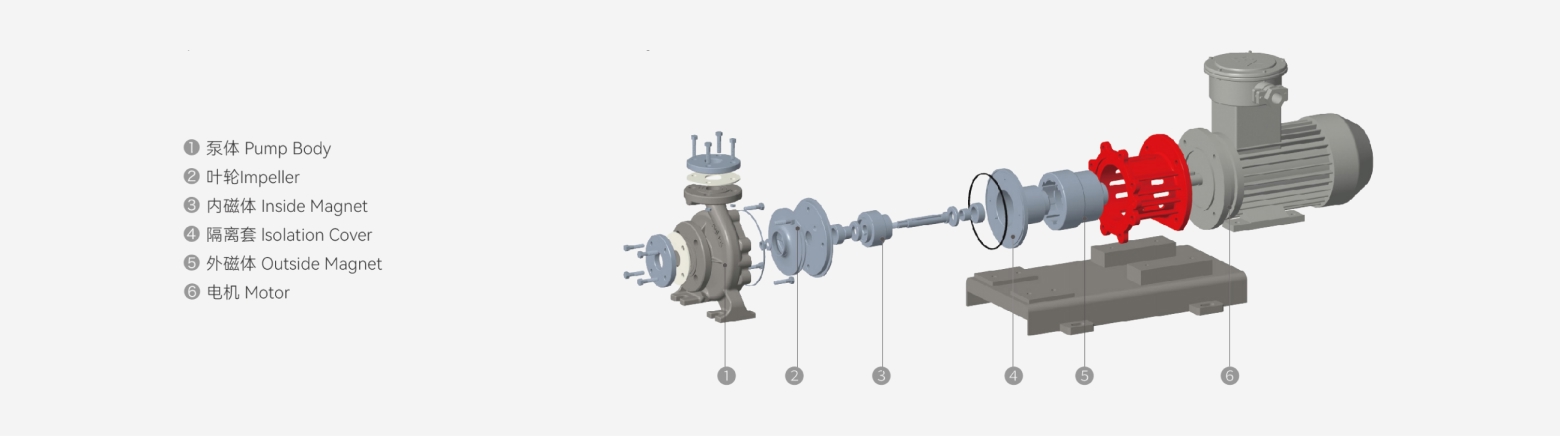

Pump Structure

The AMC Pump structure consists of the Pump Body, Impeller, Spindle, Inside Magnet, Isolation Cover, Outside Magnet, Bearing, Pump Cover, Shaft Sleeve, and Motor, forming a leak-free magnetic drive assembly .

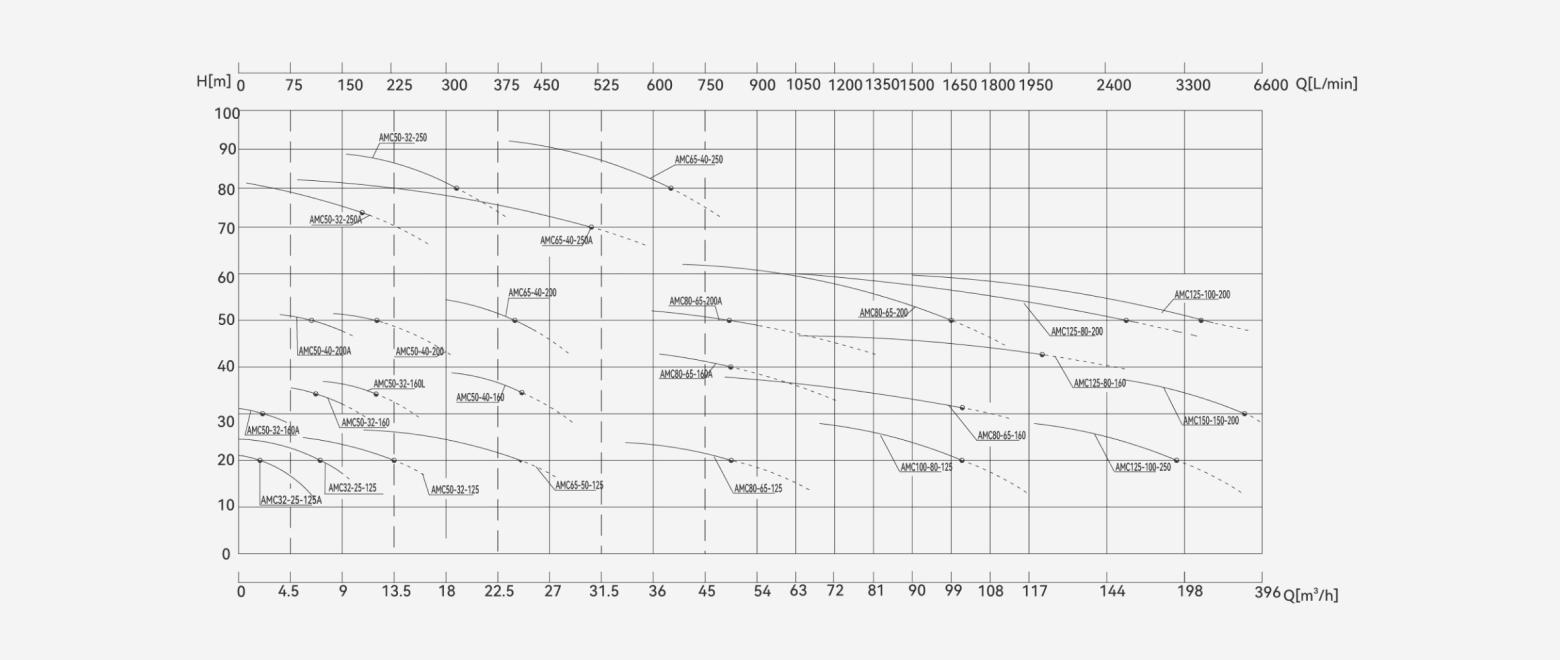

Performance Curve

The AMC Pump structure consists of the Pump Body, Impeller, Spindle, Inside Magnet, Isolation Cover, Outside Magnet, Bearing, Pump Cover, Shaft Sleeve, and Motor, forming a leak-free magnetic drive assembly .

Working Condition

| Medium Temperature | Medium Density | Ambient Temperature | Maximum Elevation | Max Withstand Pressure |

|---|---|---|---|---|

| -196°C to +400°C | 0.6 to 2.0 | -50°C to +70°C | 5000m | 40bar |

Application Area

Petrochemicals, pharmaceutical intermediates, active pharmaceutical ingredients (APIs) and traditional Chinese medicine (TCM) extractants, fine chemical fields such as chemical additives, as well as hazardous waste treatment and water treatment.

Product Certification