LMZ Light-Duty Centrifugal Magnetic Drive Pump

Product Overview

The LMZ Series represents a specialized solution for handling aggressive chemicals, acids, and alkalis where leakage is not an option. Unlike traditional pumps with mechanical seals, the LMZ utilizes a magnetic coupling drive, creating a completely hermetic liquid end that prevents hazardous spills and protects the workplace environment.

Product Features

- Advanced Silica Sol Investment Casting Process

- High/Low Temperature Resistant Magnetic Circuit Design

- Enclosed Support with Internal Anti-Frosting Function

- Single-Support Lightweight Installation Method

- Wide Operating Temperature Range

Technical Specifications

| Model | Diameter | Motor | Performance Parameter | Pump Weight (kg) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Inlet | Outlet | Power (kW) | (Hp) | Voltage (V) | Frequency (Hz) | Speed (r/min) | Rated Head (m) | Rated Capacity (m³/h) | ||

| LMZ-10 | DN32 | DN25 | 0.75 | 1 | 3ø-380 | 50 | 2760 | 15 | 4 | 28 |

| LMZ-20 | DN32 | DN25 | 1.5 | 2 | 3ø-380 | 50 | 2760 | 18 | 6 | 30 |

| LMZ-30 | DN50 | DN32 | 2.2 | 3 | 3ø-380 | 50 | 2760 | 22 | 6.3 | 42 |

| LMZ-40 | DN50 | DN32 | 3 | 4 | 3ø-380 | 50 | 2900 | 21 | 9 | 45 |

| LMZ-50 | DN50 | DN40 | 4 | 5 | 3ø-380 | 50 | 2900 | 25 | 25 | 60 |

| LMZ-60 | DN50 | DN40 | 4.5 | 6 | 3ø-380 | 50 | 2900 | 30 | 25 | 65 |

| LMZ-75 | DN50 | DN40 | 5.5 | 7.5 | 3ø-380 | 50 | 2900 | 35 | 25 | 87 |

*The above characteristic testing is based on water transfer at normal speed under 20°C. The performance parameter error is approximately ±10%. Pump performance varies depending on the proportion and density of the liquid medium.

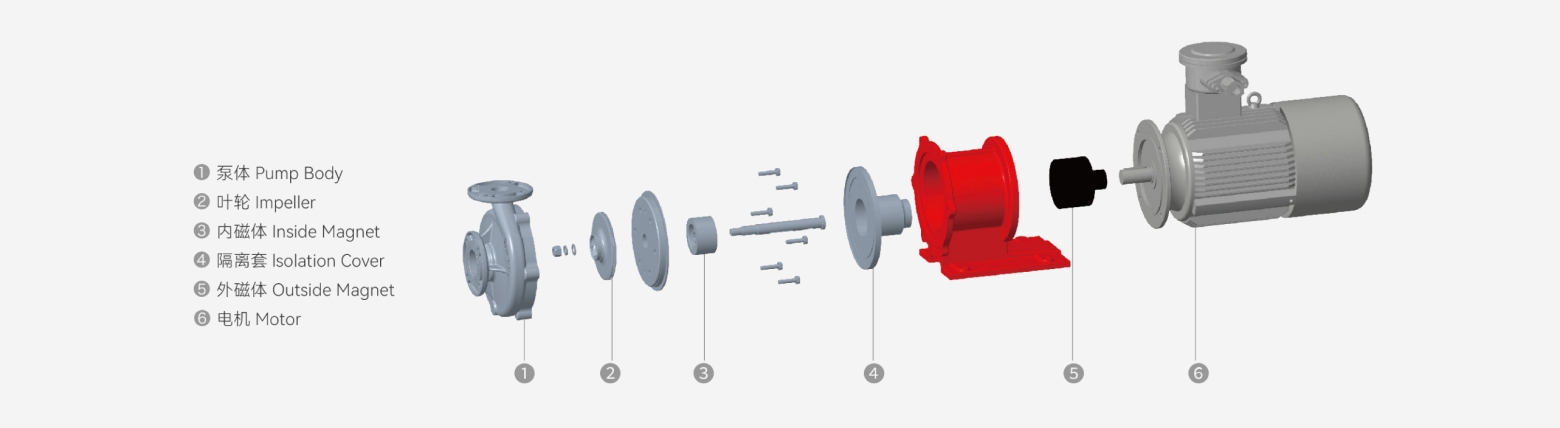

Pump Structure

The LMZ Pump structure consists of the Pump Cover, Impeller, Pump Body, Inside Magnet,, Isolation Cover, Outer Magnetic Rotor, and Motor, forming a leak-free, low-maintenance light-duty fluid transfer assembly.

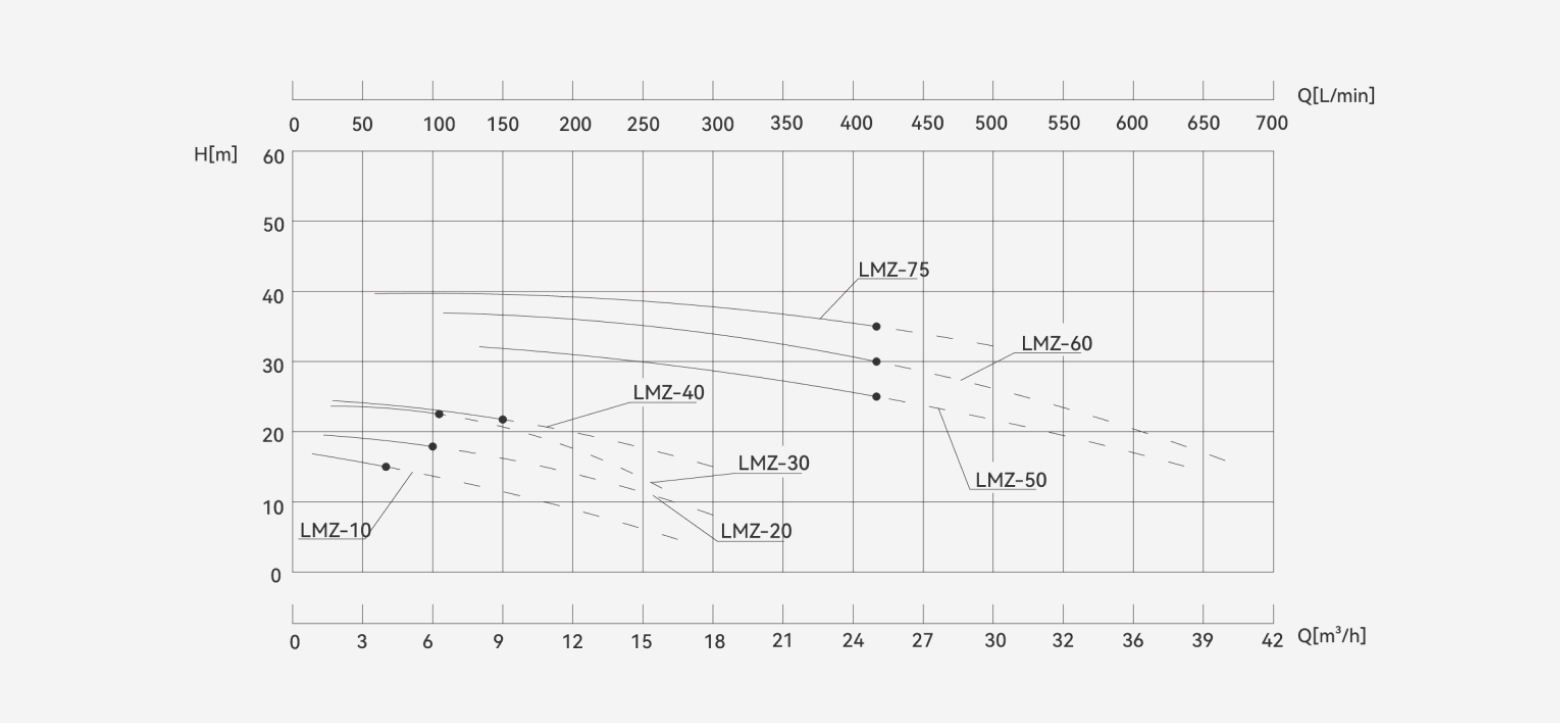

Performance Curve

The LMZ Pump structure consists of the Pump Cover, Impeller, Pump Body, Inside Magnet,, Isolation Cover, Outer Magnetic Rotor, and Motor, forming a leak-free, low-maintenance light-duty fluid transfer assembly.

Working Condition

| Medium Temperature | Medium Density | Ambient Temperature | Maximum Elevation | Max withstand pressure |

|---|---|---|---|---|

| -196°C~+400°C | 0.6~2.0 | -50°C~+70°C | 5000m | 30bar |

Application Area

High-temperature mold temperature control, high-low temperature test instruments, semiconductor precision temperature control, chemical equipment, template temperature control, ultrasonic cleaning equipment, high-end printing and dyeing equipment, vacuum distillation, metering and conveying skids, TCU temperature control systems, hydrogen generators, ozone generators, etc.