MDC-M Micro / Mini Magnetic Gear Pump

Product Overview

The MDC-M Series condenses the reliable performance of magnetic gear technology into a miniature architecture. Unlike the industrial-scale MDC-X, this series is engineered specifically for micro-flow metering and sampling, where accuracy is paramount.

Product Features

- Wide Viscosity Range for Fluid Transfer

- High Self-Priming Capacity & High Vacuum Discharge Performance

- Pulse-Free Output with High Precision

- Excellent High Temperature Resistance & Wear Resistance

Technical Specifications

| Model | Diameter | Motor | Performance Parameter | |||||

|---|---|---|---|---|---|---|---|---|

| Inlet | Outlet | Power (kW) | AC voltage (V) | DC voltage (V) | Speed (r/min) | Max Pressure (Bar) | Rated Capacity (L/min) | |

| MDC-M020 | NPT1/8" | NPT1/8" | Selected based on actual technical requirements | 3ø-380v | 12-48 | 2-3500 | 20 | 0-0.6 |

| MDC-M039 | NPT1/8" | NPT1/8" | 3ø-380v | 12-48 | 2-3500 | 20 | 0-1.3 | |

| MDC-M060 | NPT1/8" | NPT1/8" | 3ø-380v | 12-48 | 2-3500 | 20 | 0-1.9 | |

| MDC-M070 | NPT1/8" | NPT1/8" | 3ø-380v | 12-48 | 2-3500 | 20 | 0-2.2 | |

| MDC-M100 | NPT1/4" | NPT1/4" | 3ø-380v | 12-48 | 2-3500 | 20 | 0-2.9 | |

| MDC-M120 | NPT1/4" | NPT1/4" | 3ø-380v | 12-48 | 2-3500 | 20 | 0-3.9 | |

| MDC-M170 | NPT1/4" | NPT1/4" | 3ø-380v | 12-48 | 2-3500 | 20 | 0-5.4 | |

| MDC-M190 | NPT1/4" | NPT1/4" | 3ø-380v | 12-48 | 2-3500 | 20 | 0-6 | |

| MDC-M240 | NPT3/8" | NPT3/8" | 3ø-380v | 12-48 | 2-3500 | 20 | 0-8.2 | |

| MDC-M350 | NPT3/8" | NPT3/8" | 3ø-380v | 12-48 | 2-3500 | 20 | 0-10.5 | |

| MDC-M400 | NPT3/8" | NPT3/8" | 3ø-380v | 12-48 | 2-3500 | 20 | 0-12.6 | |

| MDC-M600 | NPT3/8" | NPT3/8" | 3ø-380v | 12-48 | 2-3500 | 20 | 0-18.9 | |

| MDC-M900 | NPT3/4" | NPT3/4" | 3ø-380v | 12-48 | 2-3500 | 20 | 0-28 | |

| MDC-M1200 | NPT3/4" | NPT3/4" | 3ø-380v | 12-48 | 2-3500 | 20 | 0-38 | |

| MDC-M1700 | NPT3/4" | NPT3/4" | 3ø-380v | 12-48 | 2-3500 | 20 | 0-55 | |

| MDC-M2600 | NPT1" | NPT1" | 3ø-380v | 12-48 | 2-3500 | 20 | 0-65 | |

*The above characteristic testing is based on water transfer at normal speed under 20°C. The performance parameter error is approximately ±10%. Pump performance varies depending on the proportion and density of the liquid medium.

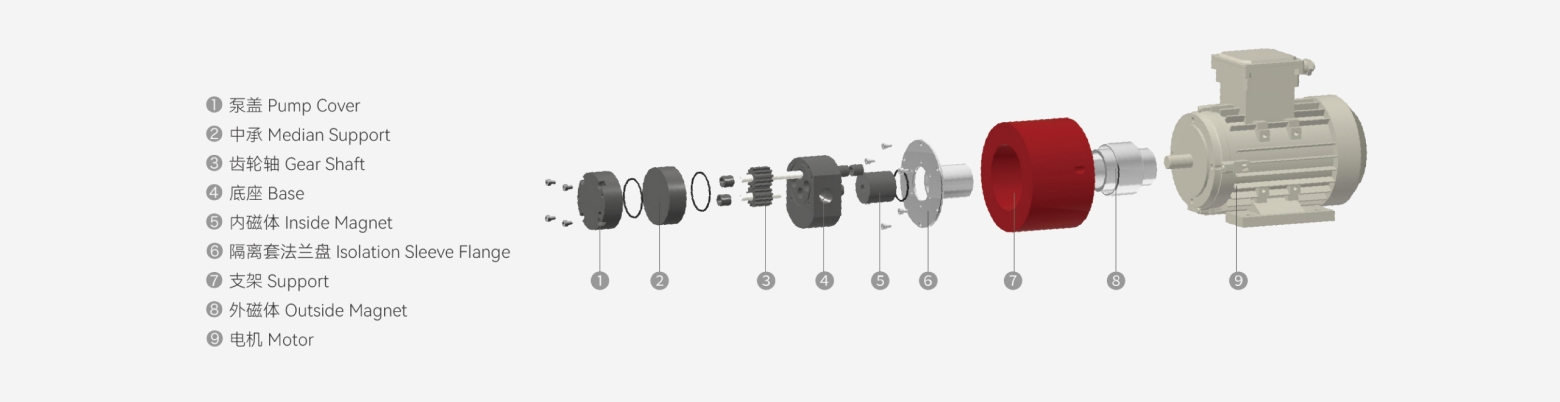

Pump Structure

The MDC-M Pump structure consists of the Pump Cover, Median Support, Gear Shaft, Base, Inside Magnet, Isolation Sleeve Flanger, Support, Outer Magnetic Rotor, and Brushless DC Motor, forming a high-precision leak-free micro fluid transfer assembly.

Working Condition

| Medium Temperature | Medium Density | Ambient Temperature | Maximum Elevation | Max withstand pressure |

|---|---|---|---|---|

| -120°C~+150°C | 0.6~2.0 | -50°C~+70°C | 5000m | 100bar |

Application Area

Chemical industry, pharmaceuticals, laboratory instruments, new energy, semiconductors, cryogenic deep cooling, distillation, spray systems, hydrogen generators, etc.