MDK Stainless Steel Vortex Magnetic Pump

Product Overview

MDK Magnetic Drive High-Low Temperature Vortex Pump features stainless steel wetted parts. Adopting a shaft seal-free, magnetic drive design, it converts dynamic seals into static seals, ensuring the pump’s safety and stability under cryogenic and high-temperature operating conditions.

Product Features

- Precision Casting with Medium-Temperature Wax & Multi-Step Surface Treatment Technology

- Ultra-High Pressure Hydraulic Technology

- Aluminum-Housed Explosion-Proof Motor

Technical Specifications

| Model | Diameter | Motor | Performance Parameter | Pump Weight (kg) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Inlet | Outlet | Power (kW) | (Hp) | Voltage (V) | Frequency (Hz) | Speed (r/min) | Max/Rated Head (m) | Max Capacity (L/min) | ||

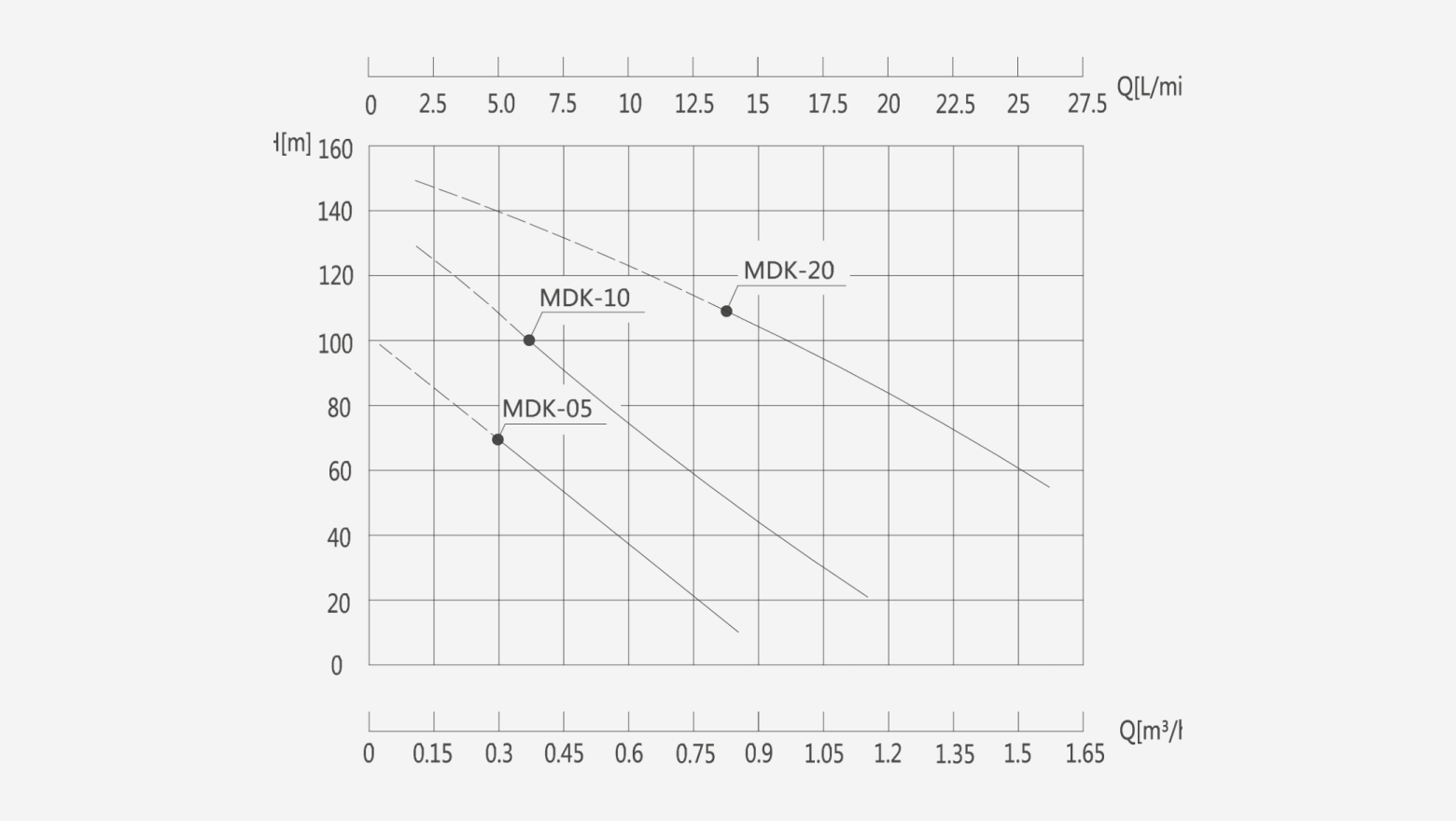

| MDK-05 | G3/4" | G1/2" | 0.37 | 0.5 | 3Φ-380 | 50 | 2760 | 100/70 | 15 | 11 |

| MDK-10 | G3/4" | G1/2" | 0.75 | 1 | 3Φ-380 | 50 | 2760 | 130/100 | 20 | 12 |

| MDK-20 | G3/4" | G1/2" | 1.5 | 2 | 3Φ-380 | 50 | 2760 | 150/110 | 35 | 18 |

*The above characteristic testing is based on water transfer at normal speed under 20°C. The performance parameter error is approximately ±10%. Pump performance varies depending on the proportion and density of the liquid medium.

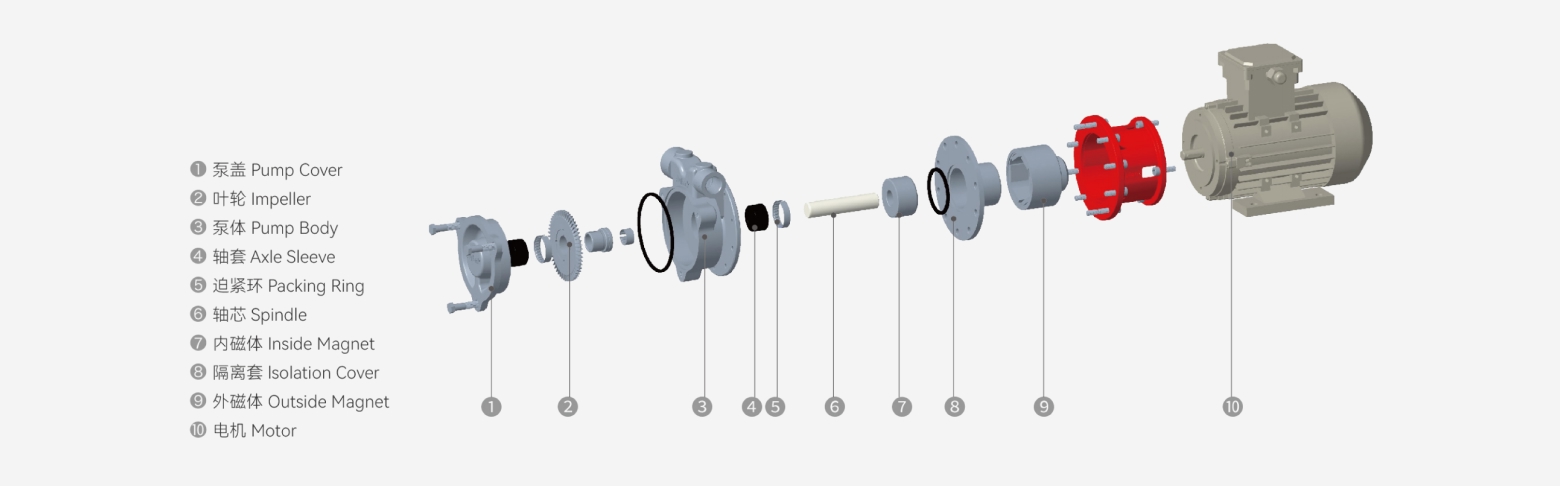

Pump Structure

The MDK Pump production structure consists of the Pump Cover, Impeller, Pump Body, Axle Sleeve, Packing Ring, Spindle, Inside Magnet, Isolation Cover, Outside Magnet, and Motor, forming a leak-proof cryogenic and high-temperature fluid transfer assembly.

Performance Curve

The MDK Pump production structure consists of the Pump Cover, Impeller, Pump Body, Axle Sleeve, Packing Ring, Spindle, Inside Magnet, Isolation Cover, Outside Magnet, and Motor, forming a leak-proof cryogenic and high-temperature fluid transfer assembly.

Working Condition

| Medium Temperature | Medium Density | Ambient Temperature | Maximum Elevation | Max Withstand Pressure |

|---|---|---|---|---|

| -196°C ~ +400°C | 0.6 ~ 2.0 | -50°C ~ +70°C | 5000m | 40bar |

Application Area

Semiconductor Precision Temperature Control, High-Low Temperature Test Equipment, Microchannel Reactors, Ultrasonic Cleaning Equipment, Chemical Equipment, Hydrogen Generators, etc.