PWH/PWD/PWM Canned Vortex Pump

Product Overview

PWH / PWD / PWM series canned motor pumps feature a hermetically sealed design for zero leakage and stable operation in high and low temperature applications. With a compact structure and reliable performance, they are widely used in mold temperature control, reactor jacket systems, steam boilers, laboratory equipment, welding cooling, food processing machinery, and temperature test systems.

Product Features

- Canned Design

- High-Low Temperature Resistance

- Compact Size

- Zero Leakage

Technical Specifications

| Model | Diameter | Motor | Performance Parameter | Pump Weight (kg) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Inlet | Outlet | Power (kW) | Power (Hp) | Voltage | Frequency (Hz) | Speed (r/min) | Max / Rated Head (m) | Max Capacity (L/min) | ||

| PWM-033(E)(S) | DN20 | DN20 | 0.25 | 0.33 | 3Φ380 / 1Φ220 | 50 | 2760 | 15 / 12 | 30 | 9 |

| PWM-05(E)(S) | DN20 | DN20 | 0.37 | 0.5 | 3Φ380 / 1Φ220 | 50 | 2760 | 28 / 22 | 42 | 9 |

| PWM-10(E)(S) | DN20 | DN20 | 0.75 | 1 | 3Φ380 / 1Φ220 | 50 | 2760 | 38 / 28 | 56 | 12.5 |

| PWD-033(E)(S) | G1/2" | G1/2" | 0.25 | 0.33 | 3Φ380 / 1Φ220 | 50 | 2760 | 25 / 16 | 22 | 6 |

| PWD-05(E)(S) | G1/2" | G1/2" | 0.37 | 0.5 | 3Φ380 / 1Φ220 | 50 | 2760 | 45 / 25 | 25 | 6.5 |

| PWD-10(E)(S) | DN20 / G3/4" | DN20 / G3/4" | 0.75 | 1 | 3Φ380 / 1Φ220 | 50 | 2760 | 60 / 40 | 60 | 11 |

*The above characteristic testing is based on water transfer at normal speed under 20°C. The performance parameter error is approximately ±10%. Pump performance varies depending on the proportion and density of the liquid medium.

Key Characteristics

Corrosion Resistant

Compact Size

Stainless Steel 316

Cast iron

Low Noise

Safe and Reliable

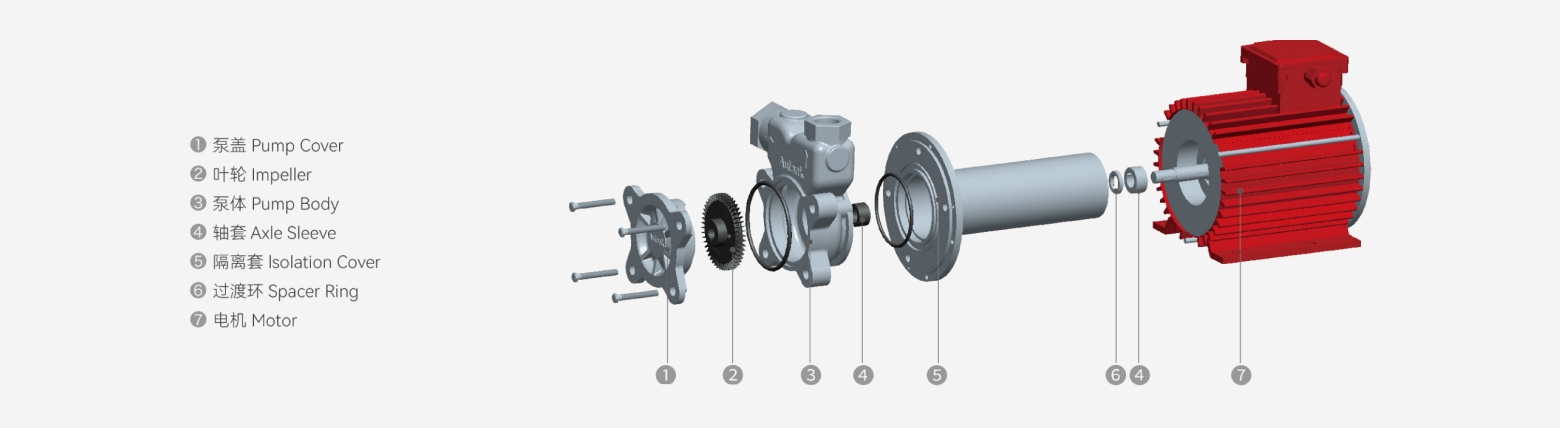

Pump Structure

PWH / PWD / PWM series canned motor pumps use a hermetically sealed motor and isolation sleeve to separate the motor from the pumped medium. The integrated pump body, impeller, axle sleeve, and spacer ring ensure stable operation without dynamic shaft seals, reducing leakage risk in continuous-duty applications.

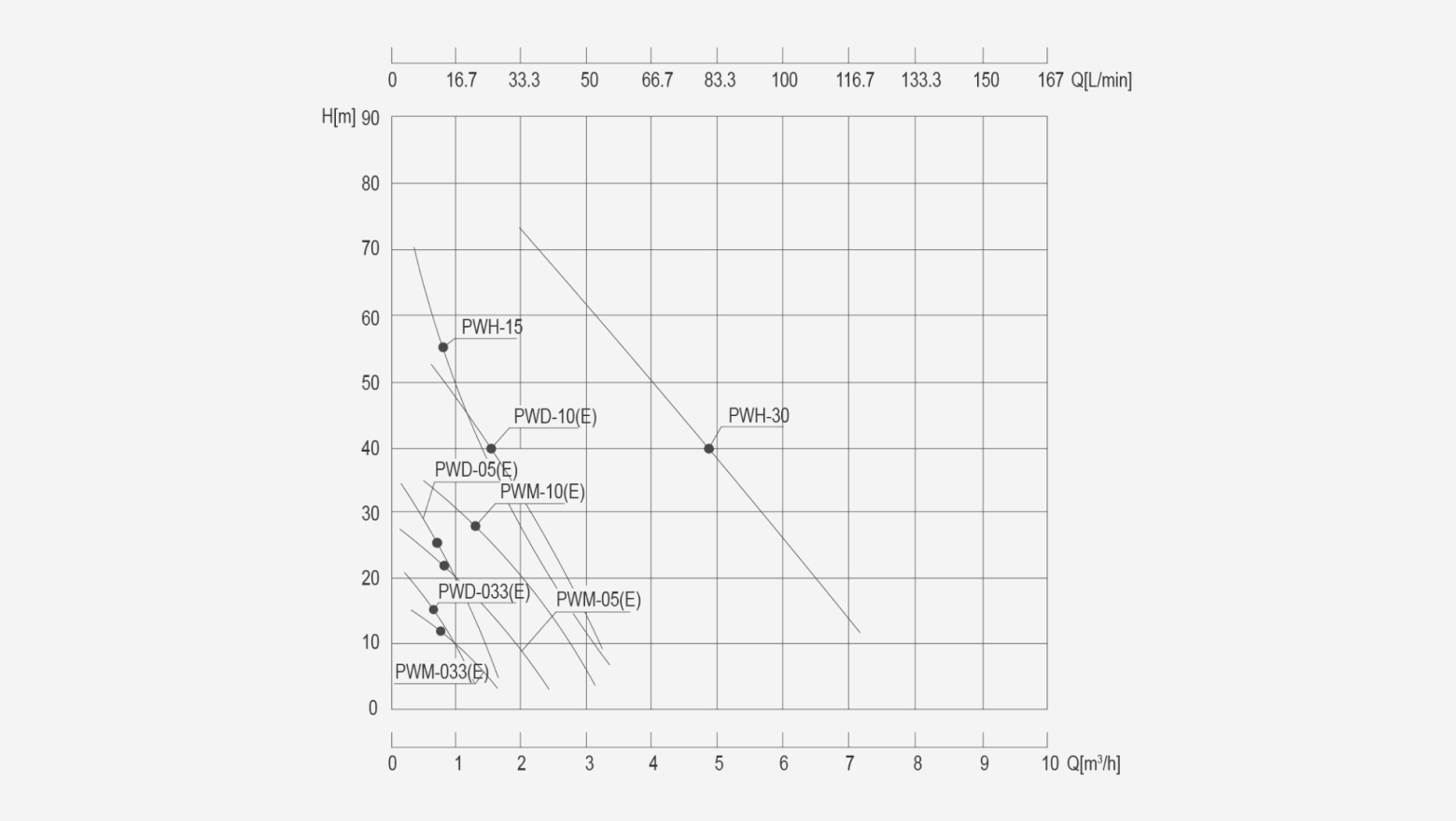

Performance Curve

PWH / PWD / PWM series canned motor pumps use a hermetically sealed motor and isolation sleeve to separate the motor from the pumped medium. The integrated pump body, impeller, axle sleeve, and spacer ring ensure stable operation without dynamic shaft seals, reducing leakage risk in continuous-duty applications.

Working Condition

| Thermal Conductivity Water | Thermal Conductivity Oil | Glycol / Silicone Oil | Ambient Temperature | Maximum Elevation | Max Withstand Pressure |

|---|---|---|---|---|---|

| +5°C ~ +130°C | +5°C ~ +130°C | 30°C ~ +130°C | -5°C ~ +40°C | 1000 m | 5.5 bar |

Application Area

Mold Temperature Control, Pharmaceutical Sterilization, Reactor Jacket Temperature Control, Steam Boiler, Welder Cooling, Test Instrument, Boiler Water Replenishment, Hot Water Furnace, Ultrasonic Cleaning, Food Machinery, Ozone Generator, High-Low Temperature Testing, etc.