WH Stainless Steel Vortex Pump

Product Overview

The WH Series Stainless Steel Vortex Pump is engineered for industrial applications requiring good corrosion resistance and reliable anti-blockage performance. Featuring a fully recessed impeller design, it creates a hydraulic vortex that allows fluid to flow through the casing with reduced blade contact.

Product Features

- Gas-Liquid Mixing

- Self-Priming Capability

- Corrosion Resistance

Technical Specifications

| Model | Diameter | Motor | Performance Parameter | Pump Weight (kg) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Inlet | Outlet | Power (kW) | (Hp) | Voltage (V) | Frequency (Hz) | Speed (r/min) | Max/Rated Head (m) | Max Capacity (L/min) | ||

| WH-05 | G3/4" | G1/2" | 0.37 | 0.5 | 3ø-380 | 50 | 2760 | 60/45 | 40 | 8 |

| WH-07 | G3/4" | G1/2" | 0.55 | 0.7 | 3ø-380 | 50 | 2760 | 80/50 | 45 | 10 |

| WH-15 | G1" | G3/4" | 1.1 | 1.5 | 3ø-380 | 50 | 2760 | 80/55 | 65 | 15.5 |

| WH-23 | G1-1/4" | G1" | 1.7 | 2.3 | 3ø-380 | 50 | 2760 | 100/60 | 120 | 20 |

| WH-33 | G1-1/2" | G1-1/4" | 2.5 | 3.3 | 3ø-380 | 50 | 2760 | 120/70 | 160 | 25.5 |

| WH-50 | G2" | G1-1/2" | 4 | 5 | 3ø-380 | 50 | 2760 | 70/50 | 220 | 40 |

| WH-75 | G2" | G1-1/2" | 5.5 | 7.5 | 3ø-380 | 50 | 2760 | 80/60 | 250 | 42 |

| WH-100 | DN65 | DN50 | 7.5 | 10 | 3ø-380 | 50 | 1470 | 70/50 | 483 | 138 |

| WH-150 | DN65 | DN50 | 11 | 15 | 3ø-380 | 50 | 1470 | 85/60 | 533 | 150 |

*The above characteristic testing is based on water transfer at normal speed under 20°C. The performance parameter error is approximately ±10%. Pump performance varies depending on the proportion and density of the liquid medium.

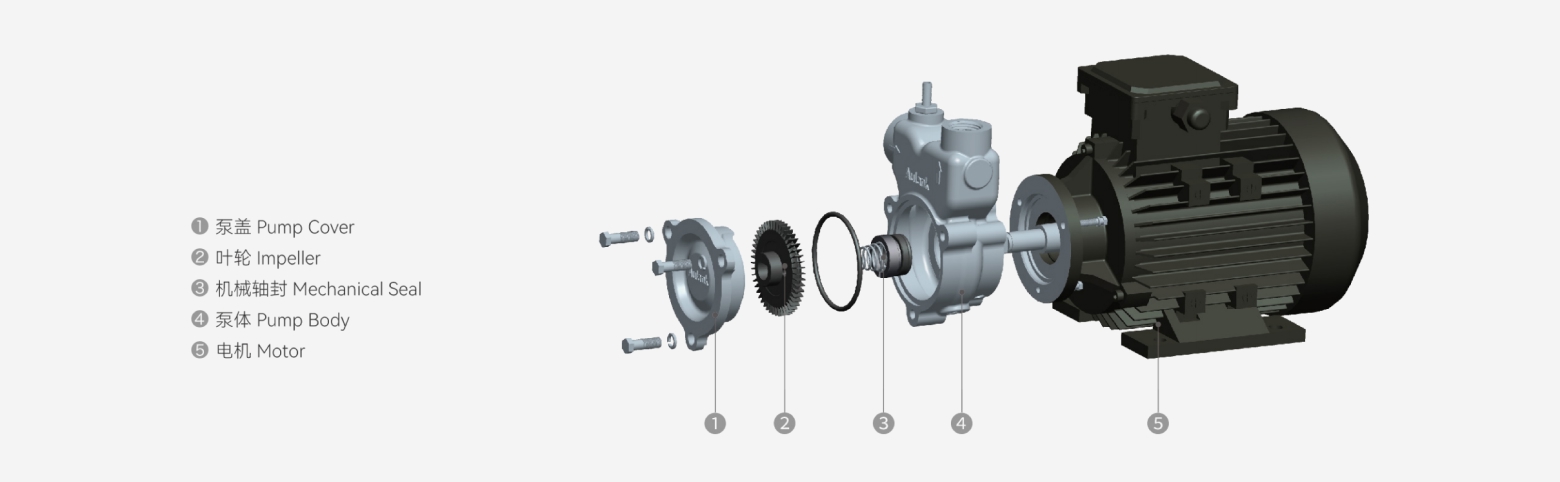

Pump Structure

The WH Pump production structure consists of the Pump Cover, Impeller, Mechanical Seal, Pump Body, and Motor, forming a corrosion-resistant self-priming gas-liquid mixing fluid transfer assembly.

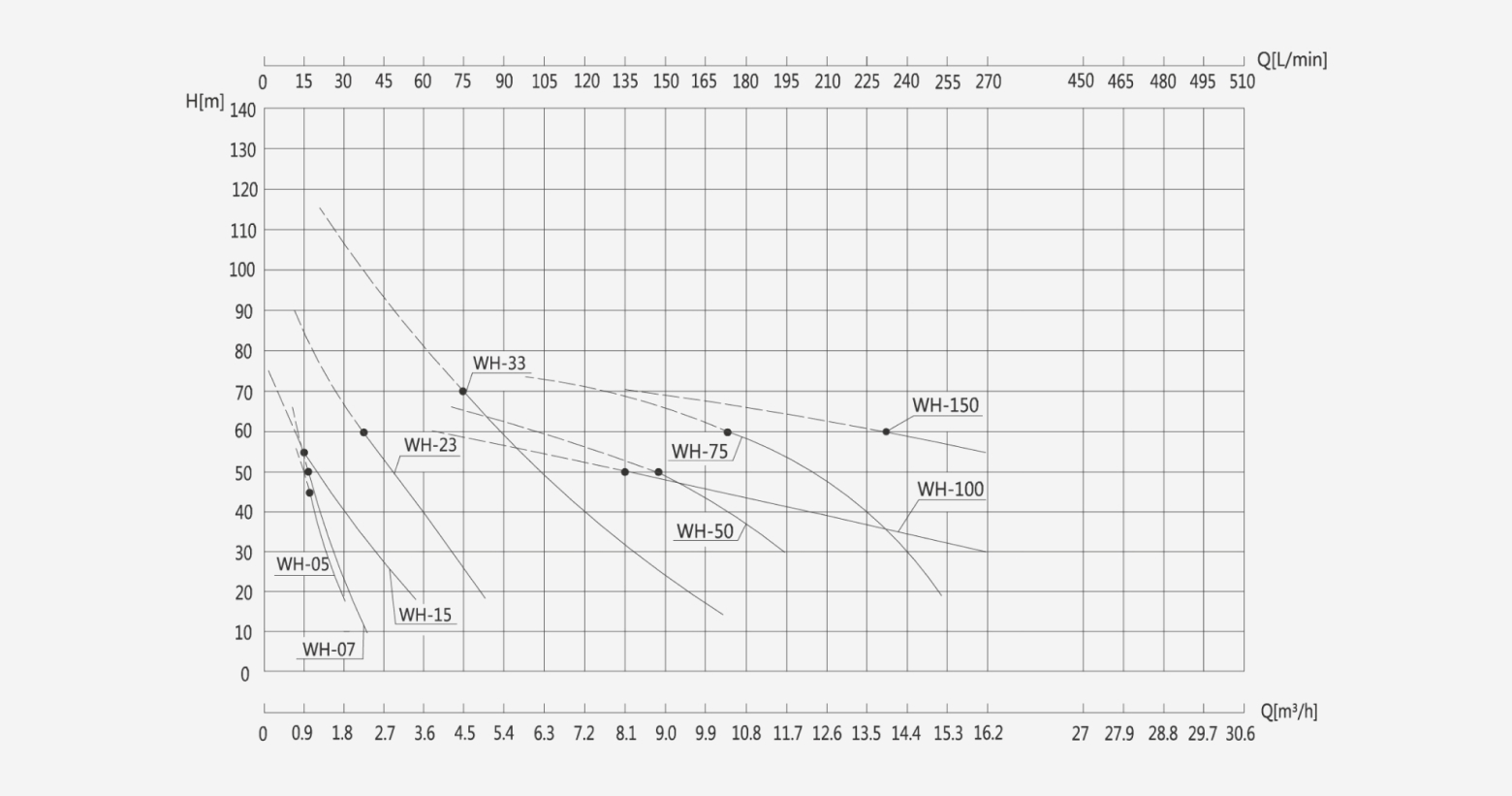

Performance Curve

The WH Pump production structure consists of the Pump Cover, Impeller, Mechanical Seal, Pump Body, and Motor, forming a corrosion-resistant self-priming gas-liquid mixing fluid transfer assembly.

Working Condition

| Thermal Conductivity Water | Thermal Conductivity Oil | Glycol/Silicone Oil | Working Temperature | Maximum Elevation | Max withstand pressure |

|---|---|---|---|---|---|

| +5°C~+160°C | +5°C~+200°C | -30°C~+180°C | -5°C~+40°C | 1000m | 10bar |

Application Area

Mold Temperature Control, Boiler Water Replenishment, Ultrasonic Cleaning, Food Machinery, Ozone Generators, High and Low Temperature Testing, etc.

Product Certification