WM Stainless Steel/Cast Iron Vortex Pump

Product Overview

The WM Series stands out by offering a choice between robust Cast Iron and corrosion-resistant Stainless Steel construction, allowing users to balance performance with budget. Designed for general industrial applications, this series utilizes a recessed vortex impeller to create a smooth, wide passage for fluids containing metal chips, sludge, or stringy fibers.

Product Features

- Diversified Options for Pump Body Materials

- Imported Sealing Materials

- Stable Performance

- Compact Structure

Technical Specifications

| Model | Diameter | Motor | Performance Parameter | Pump Weight (kg) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Inlet | Outlet | Power (kW) | (Hp) | Voltage (V) | Frequency (Hz) | Speed (r/min) | Max/Rated Head (m) | Max Capacity (L/min) | ||

| WM-033(E)(S) | DN20 | DN20 | 0.25 | 0.33 | 3ø-380 1ø-220 | 50 | 2760 | 15/12 | 30 | 9 |

| WM-05(E)(S) | DN20 | DN20 | 0.37 | 0.5 | 3ø-380 1ø-220 | 50 | 2760 | 28/22 | 42 | 9 |

| WM-10(S) | DN20 | DN20 | 0.75 | 1 | 3ø-380 1ø-220 | 50 | 2760 | 38/28 | 56 | 12.5 |

| WM-20 | DN25 | DN25 | 1.5 | 2 | 3ø-380 | 50 | 2760 | 55/30 | 110 | 18 |

| WM-30N | DN40 | DN32 | 2.2 | 3 | 3ø-380 | 50 | 2760 | 85/50 | 140 | 24 |

*The above characteristic testing is based on water transfer at normal speed under 20°C. The performance parameter error is approximately ±10%. Pump performance varies depending on the proportion and density of the liquid medium.

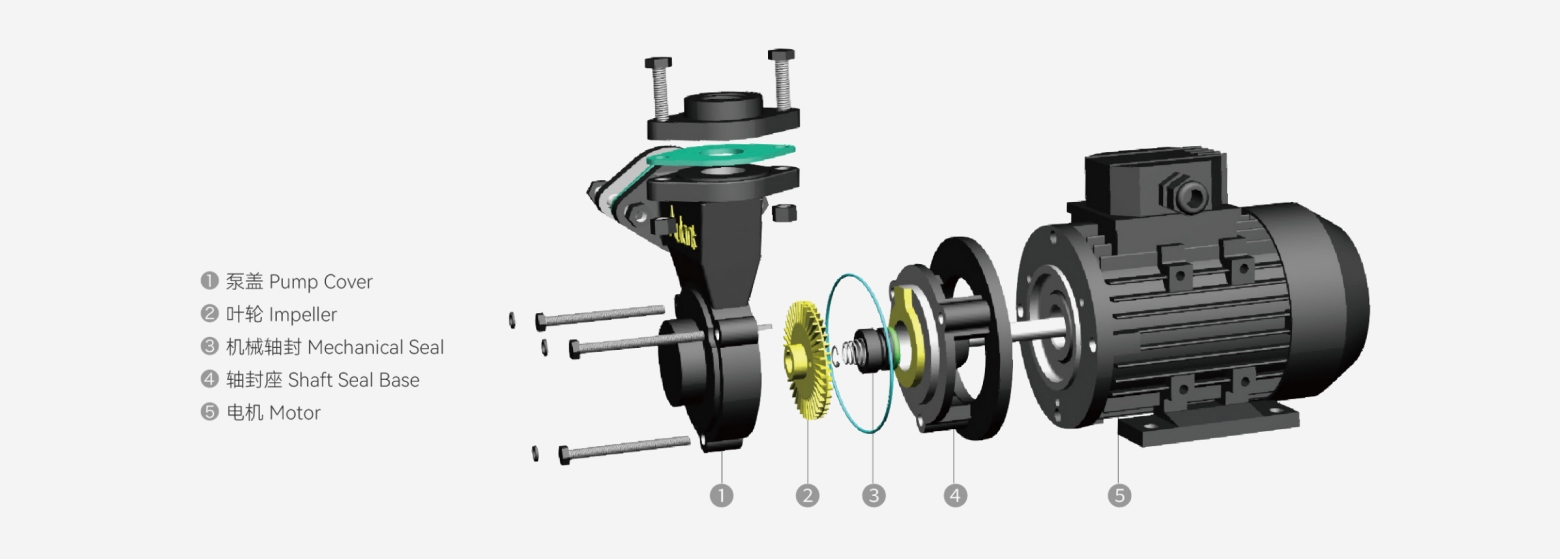

Pump Structure

The WM Pump production structure consists of the Pump Cover, Impeller, Mechanical Seal, Shaft Seal Base, and Motor, forming a compact stable-performance fluid transfer assembly with imported sealing materials.

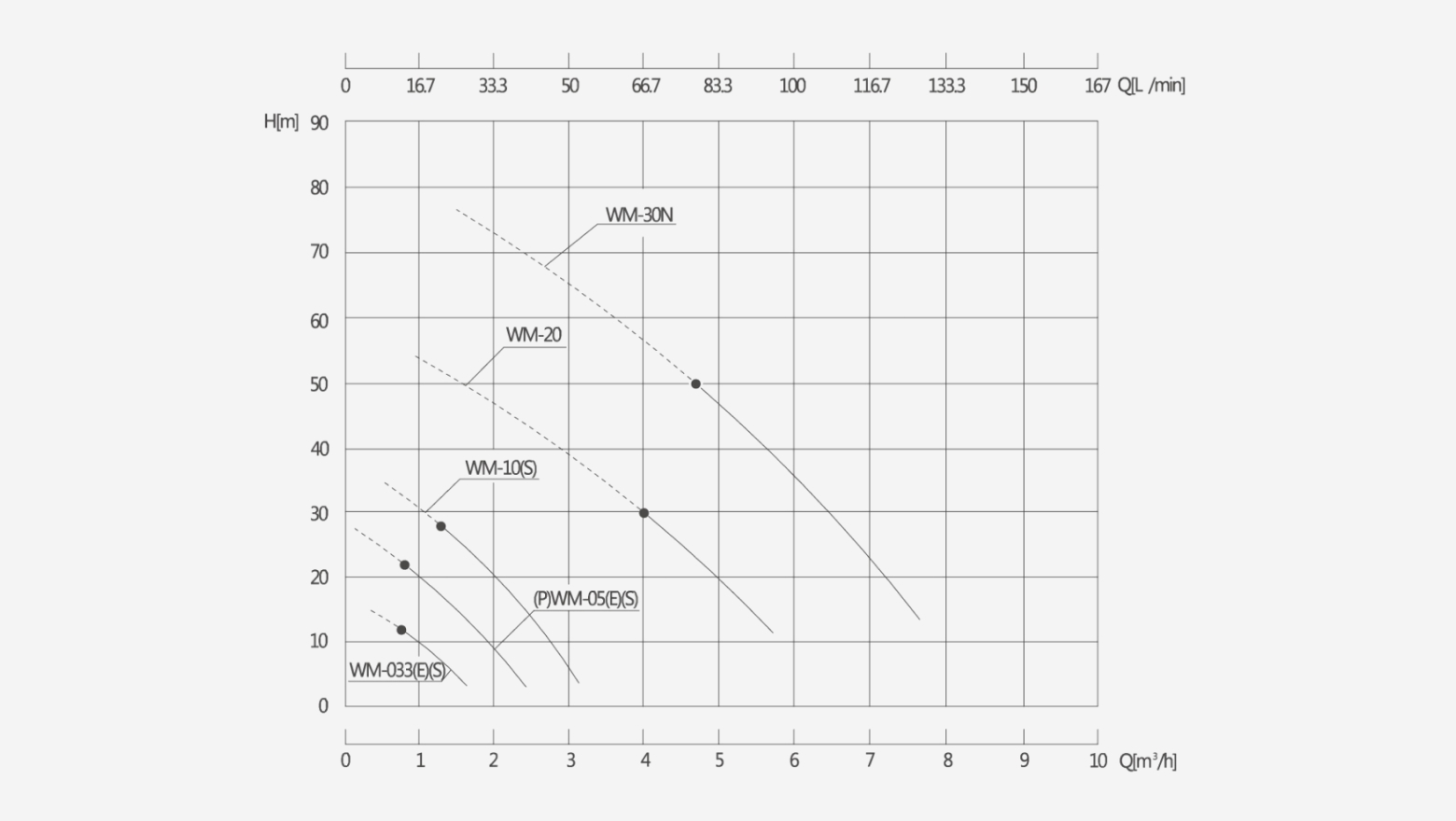

Performance Curve

The WM Pump production structure consists of the Pump Cover, Impeller, Mechanical Seal, Shaft Seal Base, and Motor, forming a compact stable-performance fluid transfer assembly with imported sealing materials.

Working Condition

| Thermal Conductivity Water | Thermal Conductivity Oil | Ethylene glycol | Working Temperature | Maximum Elevation | Max withstand pressure |

|---|---|---|---|---|---|

| +5°C~+160°C | +5°C~+200°C | -30°C~+180°C | -5°C~+40°C | 1000m | 10bar |

Application Area

Mold Temperature Control, Ultrasonic Cleaning, Test Instruments, Machine Tool Cooling, Barrel Temperature Control, Heating and Cooling Exchange Systems, etc.

Product Certification